#Tolleranza iso 2768 mk plus

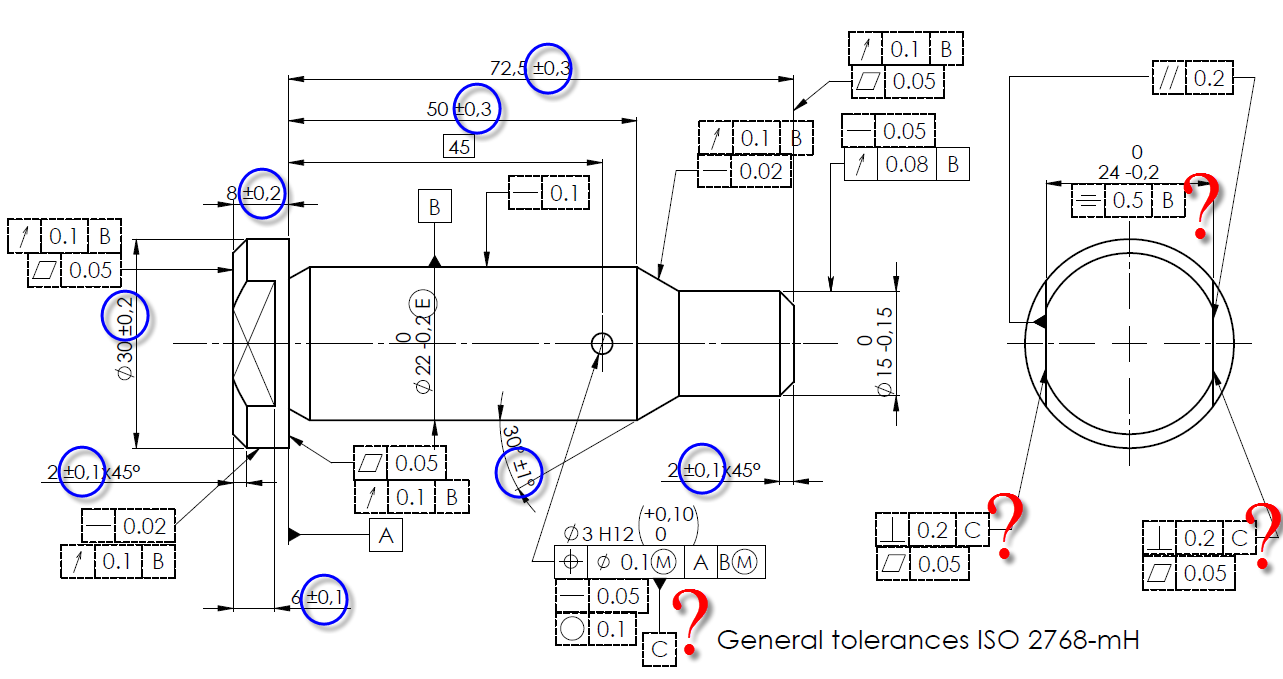

Are you sure you are not looking at H tolerance tables? The capital H is for holes and all of those are 0 to a plus number.Īfter you have used it a bit, these tolerances get easier. The +43 on the h9 tolerance is definitely wrong, all the h tolerances are +0 and a negative number. I'm using a book published by FAG Bearings that lists the complete tolerance range for each designation, I don't have my Machinerys Handbook here to check and see what is in there. General tolerances on circular run-out Unit : mm Tolerance classīearing tolerances are usually fairly tight since that controls the amount of internal clearance of the rolling elements to the race of the bearing when installed.Īn M6 tolerance on a 47mm bore should be -4 to -20 according to my book. General tolerances on symmetry Unit : mm Symmetry tolerances for ranges of nominal length Tolerance General tolerances on perpendicularity Unit : mm Perpendicularity tolerances for ranges of nominal lengths of the shorter side Tolerance class General tolerances on straightness and flatness H

General tolerances on straightness and flatness Unit : mm Straightness and flatness tolerances for ranges of nominal lengths Tolerance Permissible deviations for angular deviationsĭeviation of length (unit : mm) of the shorter side of the angle concerned Up to 10 Permissible deviations for linear dimensions of chamfered parts (Rounding of corner and chamfered dimension) Unit : mm Tolerance class Permissible deviations for linear dimensions except chamfered parts (external radii and chamfer heights, see Table 2.) Unit : mm Tolerance classįor basic dimensions below 0.5 mm, the deviations shall be indicated adjacent to the relevant basic dimension(s).

In above example “m” and “k” has defined the tolerance class. And for machined components ISO 27 68 – fh can be used. For example: For sheet metal parts ISO 27 68 – mk is used. As per design requirement and manufacturing capability tolerance class is defined. General tolerance ISO 2768 does not specify where to use these tolerance. ISO Hole Tolerances help the manufacturer to machine the parts with specified litims given by engineer. Nominal Dimension and Tolerance Zone for Holes are in mm (Metric).

0 kommentar(er)

0 kommentar(er)